Sustainability

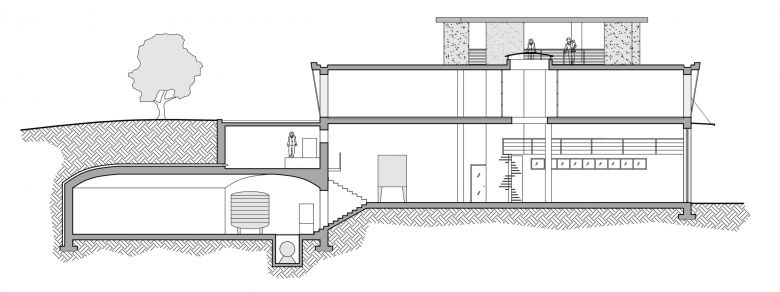

Always very focused on sustainability, we vinify in a three-level underground cellar using the gravity-fed method, moving grapes, must and wine from one level to another without using pumps, avoiding stressing the product. In addition, the thermal inertia of the underground walls allows us to avoid artificial temperature conditioning inside the cellar.

We keep humidity constant at an ideal level, lowering it by triggering a natural ventilation studied in the cellar design and increasing it by activating a small waterfall.

We are aware that we receive a most precious gift from the Earth, and for this reason we are committed to preserving and enhancing the natural resources present: maximum attention to reducing environmental impact, energy conservation and biodiversity.

Underground cellar with Gravity System

In order to minimize the impact on the environment and the surrounding landscape, the new winery was designed with a gravity-fed winemaking method, three levels below ground, to avoid the use of electric pumps to move the wines from the steel tanks into the wooden barrels.

In addition, the hygroscopic and insulating conditions of the soil, naturally maintain optimal temperature and humidity for wine aging, without energy expenditure.

Solar and Photovoltaic Panels

Part of the winery roof has been covered with solar and photovoltaic panels, and their annual output meets the winery’s needs.

Severina Natural Oasis

Surrounding the winery is a natural oasis that helps preserve the microclimate and biodiversity of the place through the preservation of insects, especially bees and earthworms, which help pollinate and regulate pests harmful to the vineyard. This aromatic garden is managed with care and tireless passion by 90-year-old Nonna Severina.

Water, a precious good

Feeding the pond, watering the garden plants and to cool some of the rooms are just a few examples of how we use and value such a precious commodity as rainwater.

To enable this, a system of gutters has been built that directs rainwater that falls near the cellar into one huge underground cistern capable of holding more than 200,000 liters. Its depth is such that it maintains a low temperature even in the hottest months.

Locally sourced barrels: back to basics

For a long time, wine producers have been buying their barrels from distant companies that use wood from territories that are not necessarily local, as we mostly do, buying them from Austria and Switzerland.

At one time, however, there were those in this area who made barrels from Chestnut or Oak wood. For this reason, for a decade now, we have started an ambitious project, trying to go back to our roots. The project is to create a wine using Oak wood grown on the Cascina Chignalungo estate, selecting the best boards, seasoning them and delivering them to the winery for processing and barrel making.

It has been a long process, but the satisfaction of being able to age our wine in barrels made from native wood grown just a few meters away from our vineyards fully fulfills Pietro’s effort and dream.

Experimental Vineyard

The Alpha vineyard is where we experiment with different vine management techniques, from different pruning techniques to the selection of different Nebbiolo clones.

Vineyards

Most of the vineyards lie on the land of “Cascina Chignalungo,” an estate where vines have been at home for centuries, even finding them on the Napoleonic map. It owns other lands, also in the municipality of Lessona, also historically planted with vineyards (Crarolo, Chioso del Bosco, Berra, etc.)

The training system is Guyot with about 4800 plants per hectare.

We use horse manure to fertilize and, for “integrated and guided pest management” in vineyard management, we use sulfur and copper.

The particular orographic conformation of the land provides natural drainage, avoiding any kind of root asphyxiation.

Pietro further reduces the production of grapes authorized by the Disciplinary, aiming for yields that do not exceed 40 quintals per hectare, thinning out as early as June-July the newly formed bunches and thus allowing the plant to concentrate colors, flavors, fragrances and aromas on the remaining bunches.

The harvest, which is always very late, generally in October, is carried out by hand-picking the bunches of grapes into crates weighing a maximum of 10-12 kg.

Supervulcan

About 300 million years ago, when there was only one continent on Earth, Pangaea, a volcano exploded erupting an immense amount of material and releasing an energy equal to 250 atomic bombs.

Between 60 and 30 million years ago, the same processes that formed the Alps uplifted and rotated the part of the Earth’s crust where the exploded Volcano was located, exposing its power system to a depth of about 30 km. This is unique in the world! It can be seen in an area encompassing Valsesia and Valsessera, as far as lapping Lake Maggiore.

Since September 2013, the Supervolcano area, in which Alto Piemonte falls, is part of the Sesia-Val Grande Geopark recognised by UNESCO.

The support of EU

Thanks to the EAFRD, European Agricultural Fund for Rural Development, we have been able to install hail nets to protect our wines from to increasingly severe weather events, as hail, which are becoming more frequent due to climate change.

The European Union invests in rural areas, and for small producers like as, these contributions are essentials to continue cultivating with passion and responsability.

STAY IN TOUCH WITH US

Subscribe to our newsletter to stay updated on the latest offers and our winery events. In the meantime, enjoy a 10% discount on your next order.

Azienda

Cascina Chignalungo

via IV Novembre, 171

13853 LESSONA (BI)

ALTO PIEMONTE - ITALY

45° 34' 23.498" N 8° 12' 32.892" E

CAMPAGNA FINANZIATA AI SENSI DEL REG. UE. N. 1308/2013

CAMPAIGN FINANCED ACCORDING TO EU REG. N. 1308/2013